Understanding Tractor Coolant Types

Tractor coolants are more than just antifreeze; they're engineered fluids protecting your engine from freezing and overheating. The two primary types are ethylene glycol (a common, cost-effective option) and propylene glycol (environmentally friendlier). Both prevent freezing and corrosion, but the best choice depends on your tractor's specific requirements. Both types require supplemental coolant additives (SCAs) to maintain effectiveness and prevent corrosion and cavitation (the formation of harmful bubbles in the coolant). For more on engine maintenance, see this guide on hardened valve seats.

Identifying Your Tractor's Coolant Needs

Before purchasing coolant, consult your tractor's owner's manual. This isn't optional; it's crucial. The manual specifies the required coolant type and any necessary additives based on your engine type. This is particularly important for wet-sleeve engines, which require specific SCAs to prevent cavitation damage. Ignoring these recommendations could void your warranty and lead to costly repairs. Did you know that using the wrong coolant can reduce engine lifespan by as much as 30%?

Selecting the Right Coolant: A Step-by-Step Process

- Consult the Owner's Manual: Your manual dictates the correct coolant type and additives. This step is paramount.

- Identify Your Engine Type: Is it wet-sleeve or dry-sleeve? This significantly affects coolant selection.

- Check Manufacturer Specifications: Your manual may reference industry standards (ASTM or SAE) to ensure coolant quality.

- Avoid Mixing Coolants: Never mix different coolant types unless the manufacturer explicitly allows it. This can create damaging sludge.

- Choose a Reputable Brand: Opt for a well-known brand to ensure quality and the correct additive package.

Safe Coolant Handling and Disposal

Tractor coolant is toxic. Safety is paramount.

- Allow Complete Engine Cooling: Hot coolant causes severe burns. Wait several hours before working on the system. This is a critical safety precaution.

- Use Personal Protective Equipment (PPE): Always wear gloves, eye protection, and long sleeves. Your safety is a top priority.

- Dispose of Coolant Properly: Never pour used coolant down the drain or on the ground. It's hazardous waste. Contact your local waste management authority for proper disposal guidelines.

Coolant System Maintenance: Preventative Measures

Regular maintenance is cost-effective.

- Schedule Flushes and Replacements: Your owner's manual provides recommended intervals (typically every 1000 operating hours or annually).

- Monitor Coolant Levels: Regularly check and top off as needed with the correct coolant. Proactive monitoring can prevent major issues.

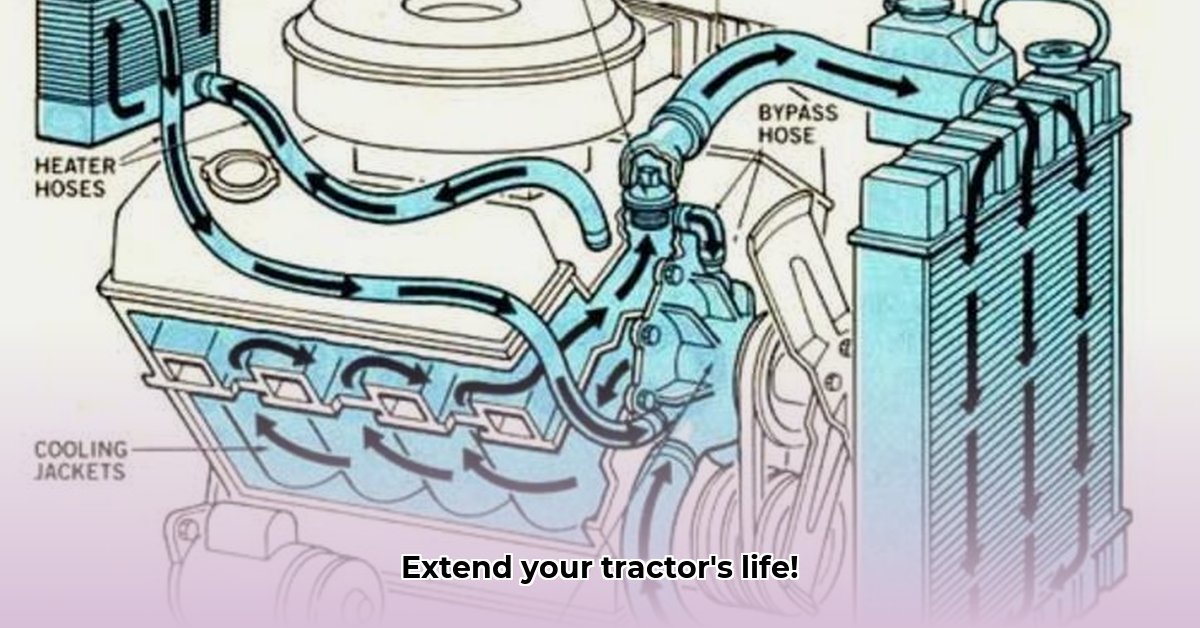

- Inspect for Leaks: Regularly inspect hoses, clamps, and the radiator for leaks. Address any leaks promptly to avoid overheating.

Troubleshooting Common Coolant Problems

- Overheating: This indicates a serious issue. Check coolant levels, radiator for blockages, thermostat function, and the water pump.

- Leaks: Inspect all hoses, clamps, and the radiator. A pressure test can help locate hard-to-find leaks.

- Coolant Contamination: Contamination reduces coolant effectiveness. A system flush and refill may be necessary.

Coolant Additives: Prioritize Manufacturer Recommendations

While advice on additives abounds online, always follow your owner's manual. Unapproved additives may void your warranty and damage your engine. Manufacturer recommendations are based on extensive testing and are tailored to your specific tractor.

Understanding the Differences: Wet-Sleeve vs. Dry-Sleeve Engines

Wet-sleeve engines have the cylinder liner directly contacting the coolant, requiring specific coolant properties to prevent cavitation damage. Dry-sleeve engines have a physical separation between the cylinder liner and the coolant, reducing the risk of cavitation. Always consult your owner’s manual for detailed guidance.

Key Takeaways:

- Understanding coolant types is crucial for engine longevity.

- Always consult your owner's manual for specific recommendations.

- Regular coolant testing and maintenance are essential.

- Safe handling and proper disposal are vital.

This guide provides a general overview. Remember to always refer to your owner's manual for specific instructions and recommendations. Proper coolant maintenance ensures your tractor's smooth and reliable operation for years to come.